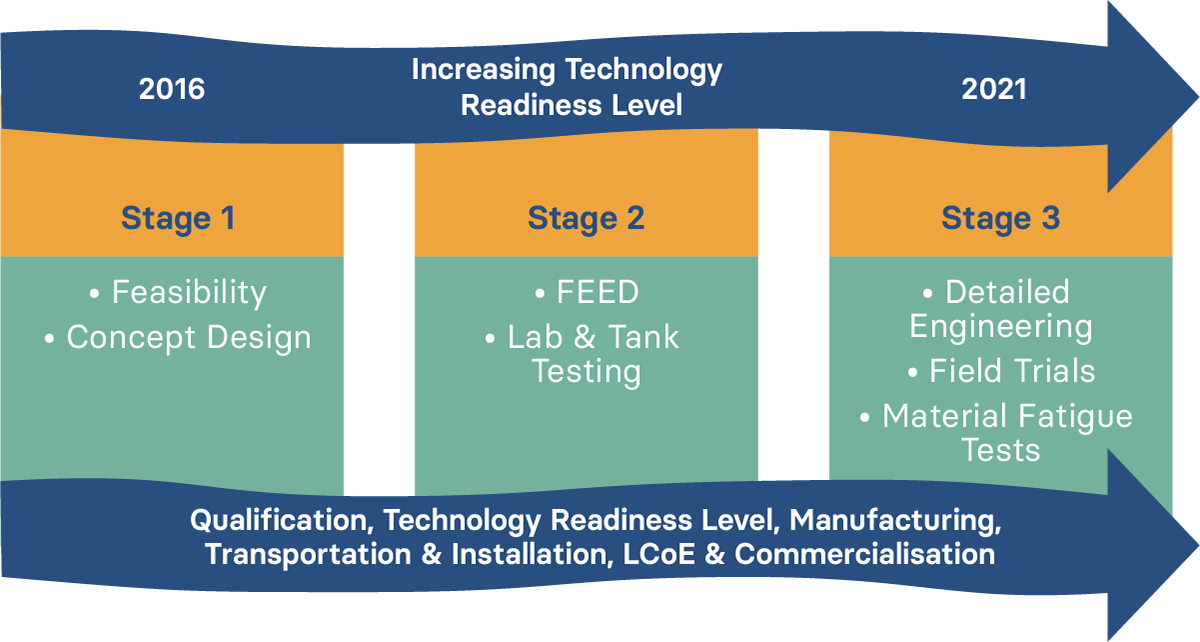

R&D Programme

Qualification of enabling technology – from concept to reality

NetBuoy™ technology has been developed by Tension Technology International Ltd under the Wave Energy Scotland (WES) precommercial procurement “Structural Materials and Manufacturing Processes” programme. The aim of this programme is to develop, demonstrate and qualify new materials and manufacturing processes which have high potential and applicability to wave energy systems and are likely to result in reduction of the levelised cost of energy. Tension Technology International Ltd began the development of NetBuoy™ in 2016 and is one of only two technology developers to reach the final stage of the WES programme, which includes included prototype field testing of a NetBuoy system.

Stage 1

The feasibility and concept stage demonstrated the excellent cost-benefit and technical viability of NetBuoy™ compared to steel-based equivalent buoys. A comprehensive landscaping and design engineering study was conducted. Manufacturability and ease of installability were used to inform the economic model. FEA and Orcaflex modelling of early designs informed the best buoy shape for material stress distribution and net load distribution.

Read the full report hereStage 2

A key aim of Stage 2 was to deliver the qualification tests and mitigate technology risk via the systems engineering approach outlined in Stage 1. Tension Technology International Ltd continued to adhere to DNVGL-RP-A203 recommended practice for the qualification of novel technology. Stage 2 involved scaled full-system manufacture and wave tank testing together with full-scale subsystem and component testing. Data acquired from these tests were used to correlate and update the numerical and FEA models developed under Stage 1. Design tools and manufacturing and installation know-how were then applied to optimise the design and update the levelised cost of energy and commercialisation.

Read the full report hereStage 3

Stage 3 includes field prototype testing, laboratory material and further tank testing to demonstrate the applicability of NetBuoy™ to alternative wave energy system architectures. Further work has been conducted to extend this applicability to other marine sectors. A NetBuoy™ prototype was designed, manufactured and installed in the Cromarty Firth in November 2020 for a 6-month deployment period. The purpose of the field trials was to demonstrate handleability and installability and mitigate the residual risks from Stage 2, which could only be addressed by installing a large system in a real environment. Learning from field testing includes the propensity to accumulate biofouling, environmental degradation and interactions between the Net and Buoy subsystems. More detailed biofouling studies have been conducted by Heriot-Watt University on candidate rubber samples deployed at EMEC's Scapa Flow site for a period of 6 months.

Current Status

On 4 June 2021 Tension Technology International Ltd retrieved the Cromarty Firth NetBuoy™ following the six months of sea trials funded by Stage 3 support from Wave Energy Scotland. The successful trials served to assess the effect on NetBuoy™️ of long-term exposure to sea water, environmental loading, biofouling and UV and ozone. The trials significantly advance technical and commercial readiness of NetBuoy™ in preparation for exploring new markets. Although vital, sea trials represent only one element of the project, so in July 2021 we returned to the wave tank to demonstrate the applicability of NetBuoy™ to other wave energy converters in addition to point absorbers.

Use our NetBuoy™ design tool.

Use NowSuppliers & subcontractors